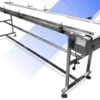

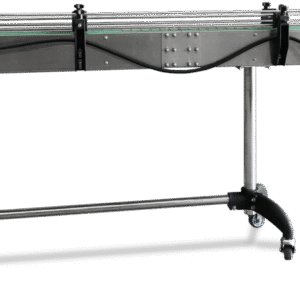

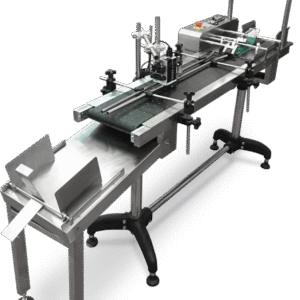

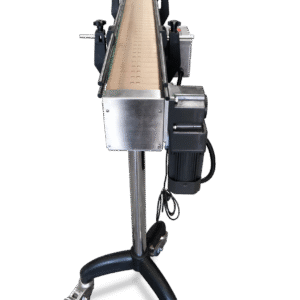

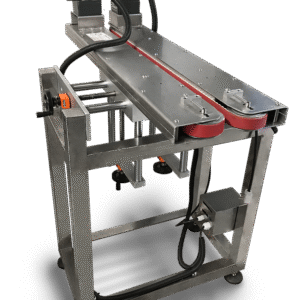

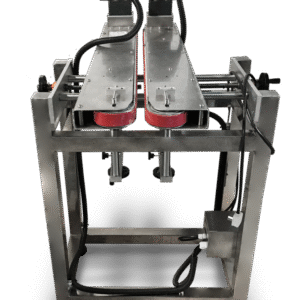

Slat Belt Conveyor

Slat Belt Conveyors utilize interlocking slats to move products along an assembly line. They are particularly useful for transporting heavy or bulky items and can be designed to navigate curves or inclines, making them versatile for various industrial applications.