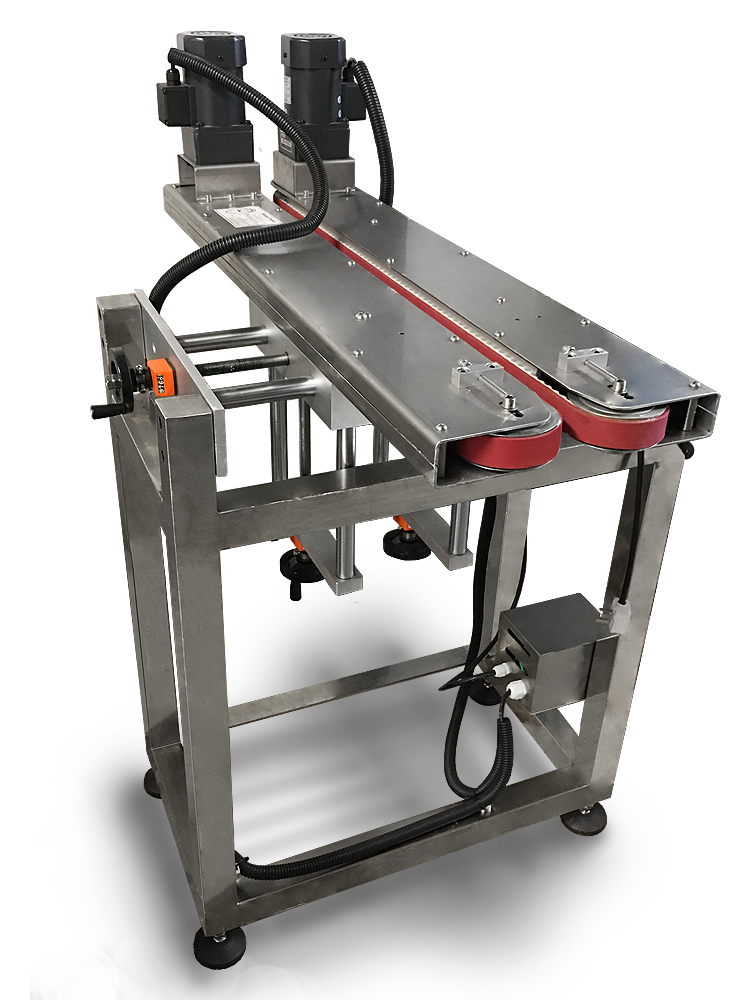

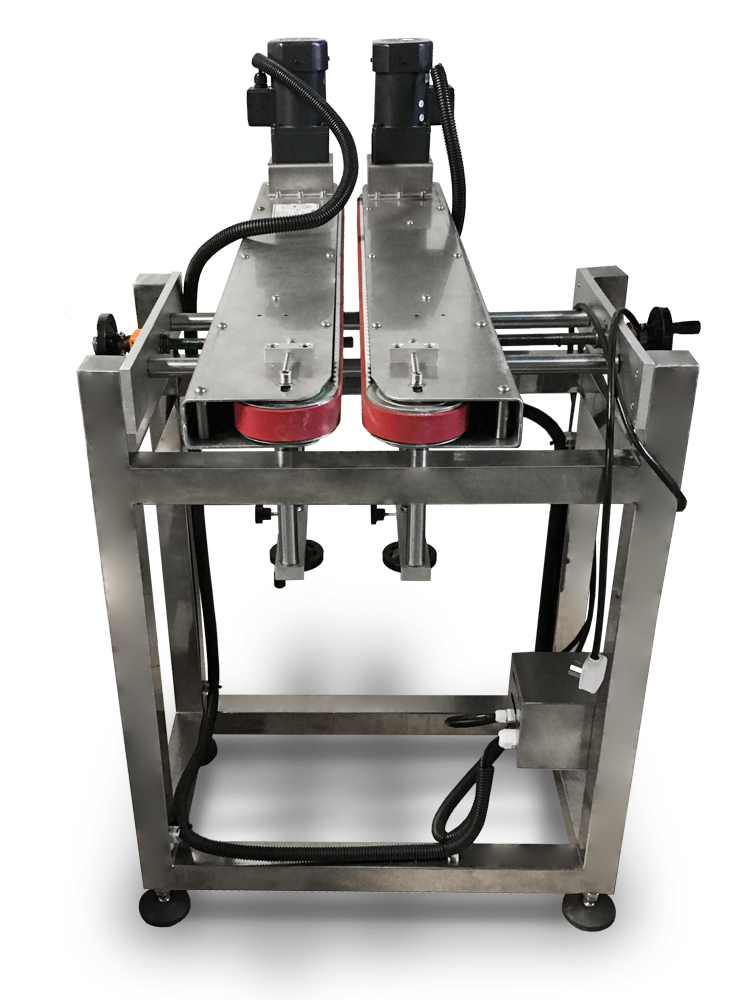

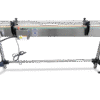

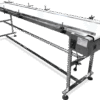

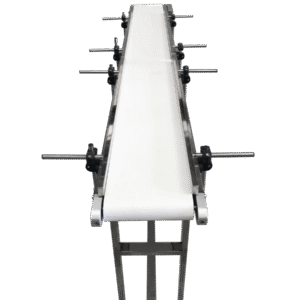

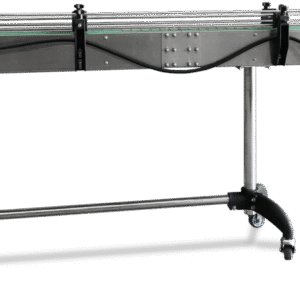

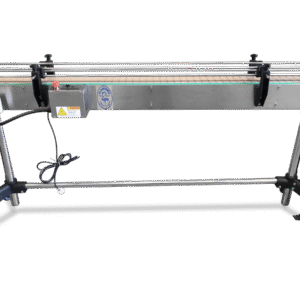

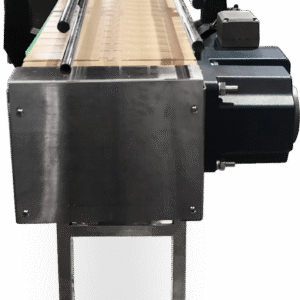

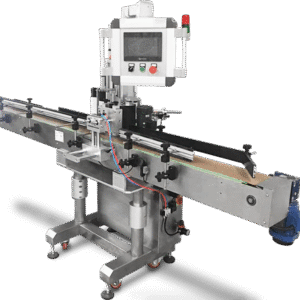

Twin Belt (Hugger Type) Conveyor

The Flamingo Twin Belt Hugger Conveyor is designed for smooth, secure bottle transfer and is ideal for applications such as underside bottle coding. Its adjustable twin belts gently hug bottles to prevent movement or tipping, ensuring precise handling throughout your production line.

Key Features:

-

Variable speed control for optimized conveyor flow

-

Adjustable height for seamless integration with different equipment

-

Adjustable distance between twin belts to accommodate various bottle sizes and shapes

-

Approximate belt length of 800mm for compact, efficient operation ( Drawings supplied on request)

-

Customizable design tailored to customer bottle samples for perfect fit and performance

-

Single-phase 240V power supply for easy installation and operation

-

Durable construction suitable for hygienic and industrial environments

Benefits:

-

Ensures stable, controlled bottle transfer for high-precision coding or labeling

-

Flexible adjustments make it compatible with a wide range of container sizes and production setups

-

Smooth operation reduces risk of product damage or misalignment

-

Easily integrates into existing production lines, boosting overall efficiency

The Flamingo Twin Belt Hugger Conveyor offers a reliable, versatile solution for manufacturers needing precise bottle handling, especially for underside coding or marking processes. Custom options available to perfectly suit your production needs.

Related products

Conveyors

Conveyors

Conveyors

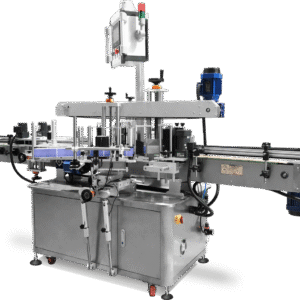

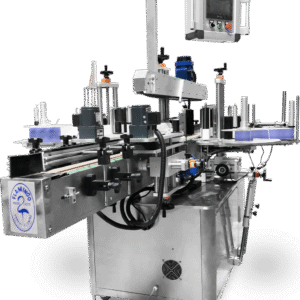

Labelling

Conveyors

Conveyors

Conveyors

Labelling