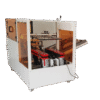

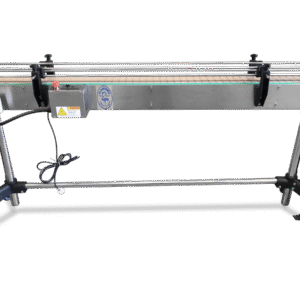

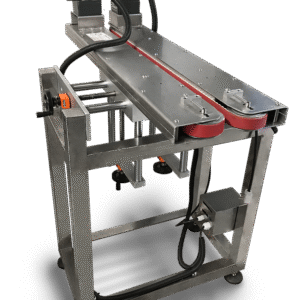

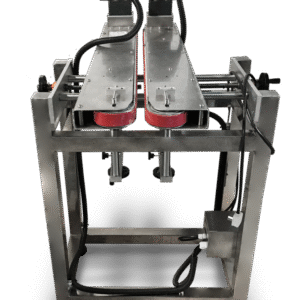

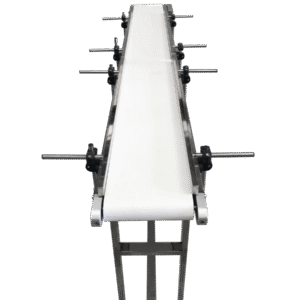

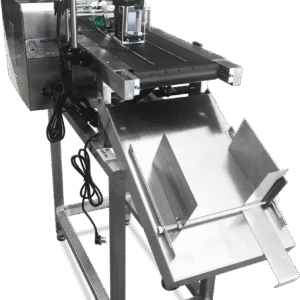

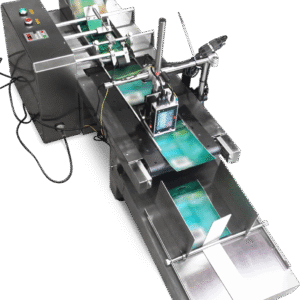

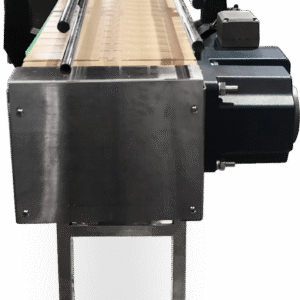

Flat Belt Conveyor

Flat Belt Conveyors consist of a continuous flat belt that moves on a flat surface or rollers, ideal for transporting light to medium-weight items over short to medium distances. They are widely used in manufacturing lines for assembly operations and packaging processes.