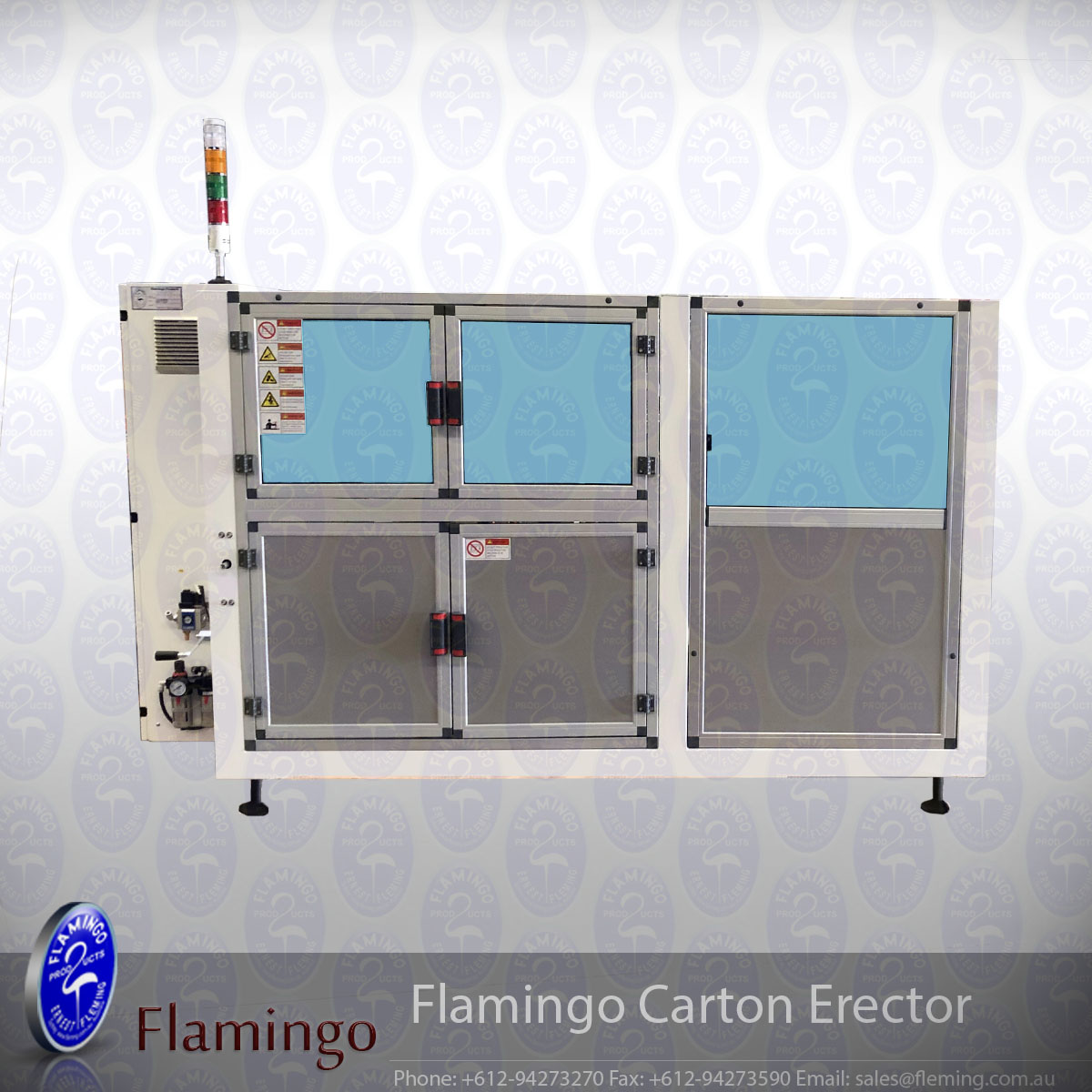

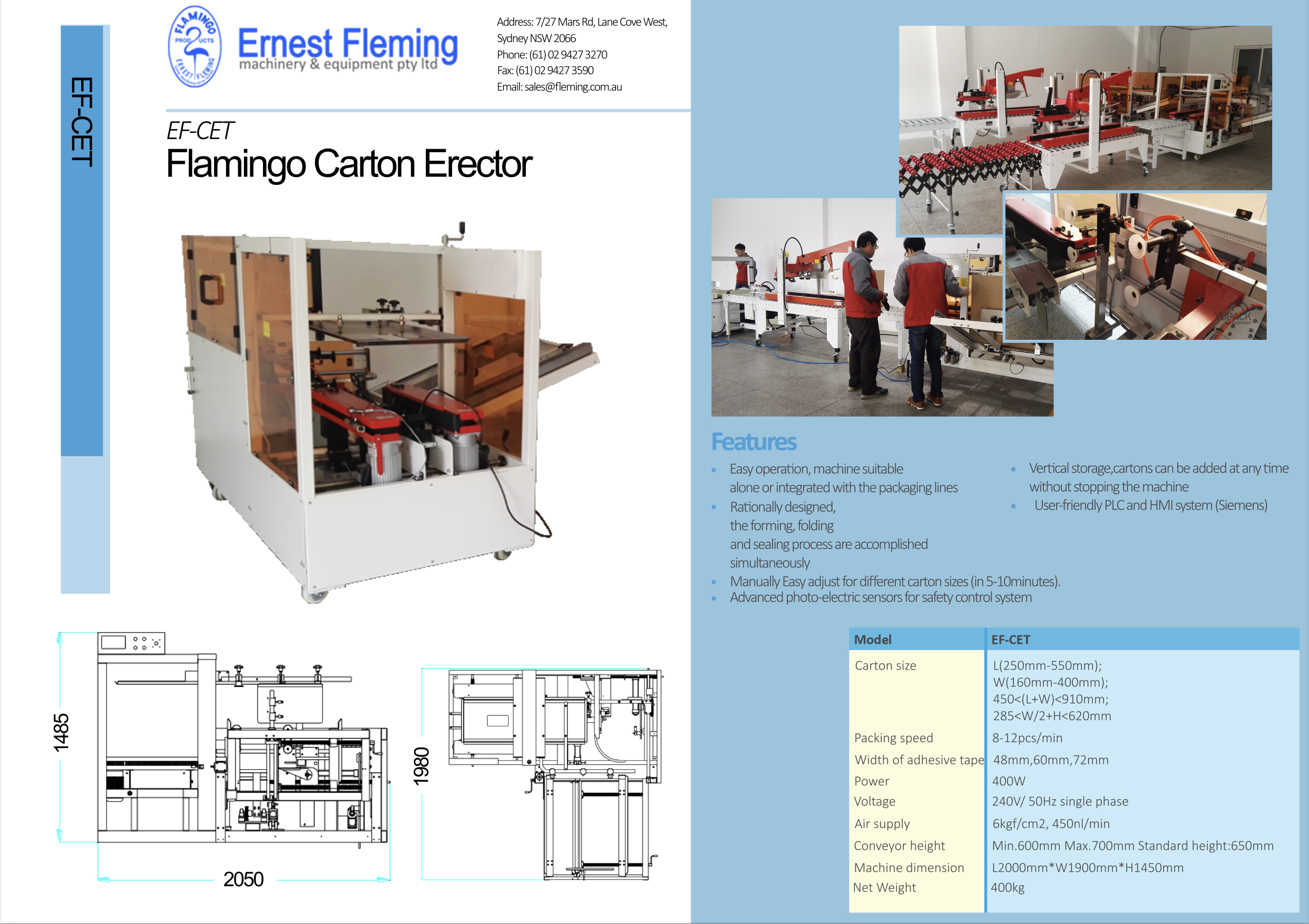

Carton Erector (Case Erector)

A Carton Erector, or Case Erector, automates the process of forming and sealing the bottom of flat, prefolded cartons. This machine streamlines packaging operations by quickly preparing boxes for product insertion, reducing labor costs and minimizing errors.

How Does It Work?

Carton erecting machines operate through a series of automated steps. Here’s a simplified overview of the process:

*Loading: Flat, folded cartons are loaded into the machine’s magazine.

*Erecting: The machine uses mechanical arms or suction systems to open and form the cartons into their final shape.

*Folding and Gluing: The erected carton is then folded and glued to ensure it holds its shape. This process can involve hot-melt glue or pressure-sensitive adhesives.

*Quality Control: Some machines are equipped with quality control systems to check for proper carton formation and adhesive application.

*Output: The finished cartons are discharged and can be filled with products or sent to additional packaging processes.

Benefits of Using Carton Erecting Machines

*Increased Efficiency: Automated carton erecting machines can produce hundreds to thousands of cartons per hour, vastly outperforming manual processes in speed and consistency.

*Reduced Labor Costs: By automating the carton formation process, businesses can reduce their reliance on manual labor, leading to cost savings and freeing up staff for other tasks.

*Enhanced Precision: These machines ensure that cartons are formed to precise specifications, minimizing errors and ensuring a consistent quality of packaging.

*Versatility: Modern carton erecting machines are designed to handle a wide range of carton sizes and types, making them suitable for various industries and product types.

*Improved Safety: Automation reduces the risk of injuries associated with manual handling and assembly, contributing to a safer workplace environment.

What to Consider When Choosing a Carton Erecting Machine

1. Production Needs: Assess your production volume and speed requirements. Choose a machine that can meet or exceed your production needs.

2. Carton Types and Sizes: Ensure the machine is compatible with the types and sizes of cartons you need to produce.

3. Ease of Operation: Look for machines with user-friendly interfaces and easy setup processes to minimize training time and operational complexities.

4. Maintenance and Support: Consider the availability of maintenance services and technical support to keep the machine running smoothly.

5. Cost and ROI: Evaluate the initial investment against potential savings in labor costs and increased production efficiency to determine the machine’s return on investment.

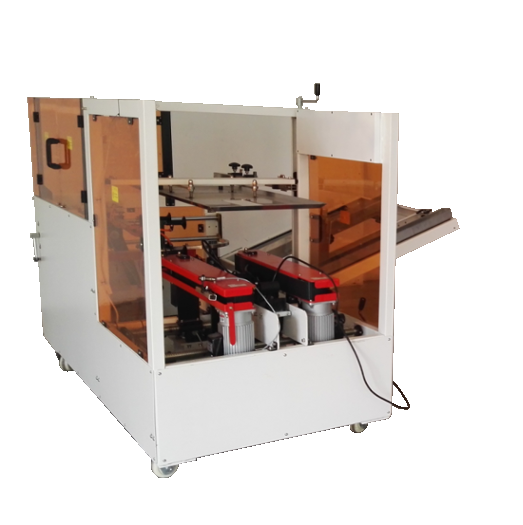

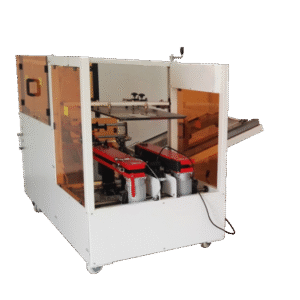

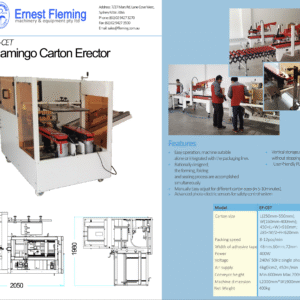

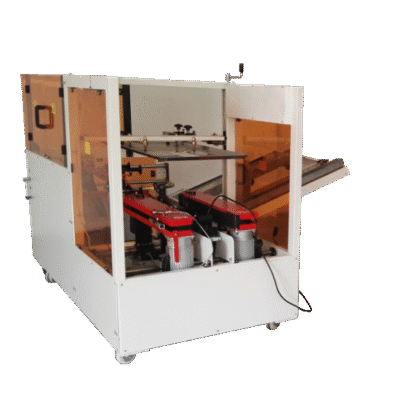

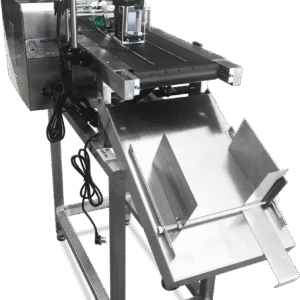

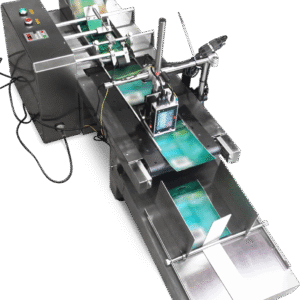

Spotlight on Feida’s Carton Erecting Machine

Feida’s carton erecting machine exemplifies cutting-edge automation in packaging, showcasing its advanced capabilities by forming a diverse range of cartons. Designed to handle materials such as cardboard, paperboard, and corrugated paper, this fully automatic system is particularly adept at creating food packaging solutions, including burger boxes, hot-dog trays, take-away containers, fries boxes, and lunch boxes. Its versatility ensures that each carton meets the highest standards, making it an ideal choice for various food packaging needs.

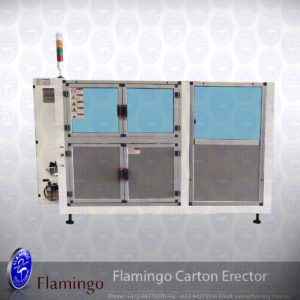

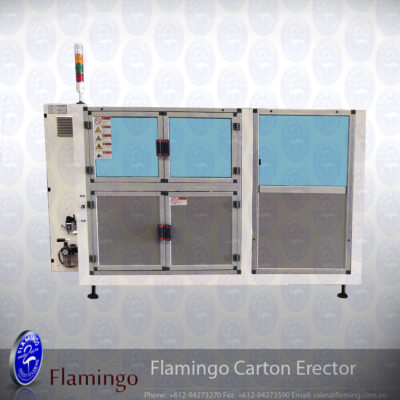

Related products

Packaging Equipment

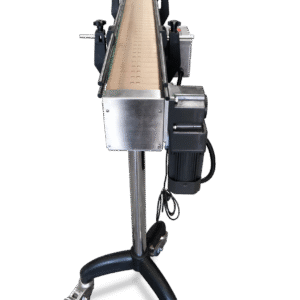

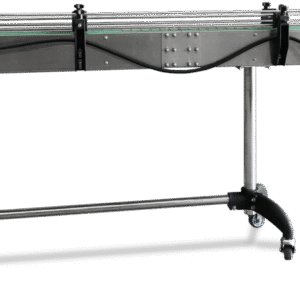

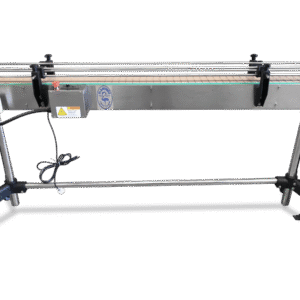

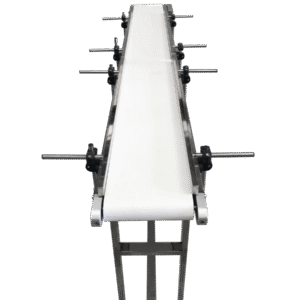

Conveyors

Conveyors

Conveyors

Conveyors

Conveyors

Packaging Equipment

Conveyors